OUR

FOUNDATION

OUR FOUNDATION

Volontà Italia’s first plant was built near the Minerbio industrial park in bologna. Volontà Italia’s other plant is used to produce oil paints. At the same time, it is also ready to produce water-based paint.The current area of the bologna factory is 50,000 square meters. It has 200 employees, 40 chemical experts and more than 2,000 products, serving more than 60 worldwide.A country. This is what Volontà has achieved.

Volontà

Volontà was founded in porto alegre, brazil, in 1927. The company Has long been involved in the development and development of paint formulation. Production, after nearly a centuryof accumulation, remains the core competitive Part of renner’s pride.today renner herrmann s.a.has become a diversified International industrial conglomerate. Its products have also been extendedto include Gold.it belongs to packaging, afforestation, derivatives of dairy products, wood and Furniture, etc., and always maintain high quality of products.sex, lead the market Demand to upgradeand upgrade continuously. Founded in 2004 in bologna, italy, in bologna, the company is dedicated to developing And producingquality top quality.environmental friendly wood paint products. With nearly 50 world top coatingsr&d engineers, the products are sold to over 40 countries.

Volontà

Volontapaint COMPANY PROFILE

V o l o n t a p a i n t

Volontà COMPANY PROFILE

Volontà was founded in porto alegre, brazil, in 1927. The company Has long been involved in the development and development of paint formulation. Production, after nearly a centuryof accumulation, remains the core competitive Part of Volontà’s pride.today Volontà herrmann s.a.has become a diversified International industrial conglomerate. Its products have also been extendedto include Gold.it belongs to packaging, afforestation, derivatives of dairy products, wood and Furniture, etc., and always maintain high quality of products.sex, lead the market Demand to upgradeand upgrade continuously. Founded in 2004 in bologna, italy, in bologna, the company is dedicated to developing And producingquality top quality.environmental friendly wood paint products. With nearly 50 world top coatingsr&d engineers, the products are sold to over 40 countries.

OUR OWN SPECIAL TECHNOLOGY

The chemists of Volontà italia worked closely with their clients,solve technical problems timely and effectively,and develop the highest quality.wood lacquer is under strict environmental protection laws and regulations will force the wood work paint market will soon change to the water-based Coating Volontà italia and Volontà global alliance Have.be prepared to meet this challenge.

Today, we have independently developed 24 kinds of resins (1,500 tons/year), which are used in more than 150 different recipes! That means we can follow the customer different requirements, timely adjust the Physical and chemical properties of our products.Volontà’s remarkable r&d centre is at the heart of Volontà, Italy part. The company has a long-term reserve of high – quality chemical professionals to form a Professional team. And through their efforts, constantly update the product formulation, research and Development new.type resin, improve the product quality. The team of 40 experts is divided into two parts.Committed to continuous innovation in product research. Especially for water-based paint development and uv Varnish drying.

R&D AND PRODUCTION CAPACITY

R&D AND

PRODUCTION CAPACITY

Materials, solvent – based wood coatings, Glass paint, fire retardant paint, etc. Productcovering water, pu, uv,Etc., nearly 8000 products. Each product is subject to rigorous testing before it is formally produced, Including.weather resistance, lightresistance, chemical resistance, Scratch resistance,cold and heat cycle, etc. Automatic computer control production ensures the stabilityof the product.The main raw material used in rena paint – resin is alsodeveloped by the Company itself.production, furtherguarantees the coating product Professionalism and applicability.

Materials, solvent – based wood coatings, Glass paint, fire retardant paint, etc. Productcovering water, pu, uv,Etc., nearly 8000 products. Each product is subject to rigorous testing before it is formally produced, Including.weather resistance, lightresistance, chemical resistance, Scratch resistance,cold and heat cycle, etc. Automatic computer control production ensures the stabilityof the product.The main raw material used in rena paint – resin is alsodeveloped by the Company itself.production, furtherguarantees the coating product Professionalism and applicability.

Volontà's

Global Allance

R&D AND

PRODUCTION CAPACITY

Materials, solvent – based wood coatings, Glass paint, fire retardant paint, etc. Productcovering water, pu, uv,Etc., nearly 8000 products. Each product is subject to rigorous testing before it is formally produced, Including.weather resistance, lightresistance, chemical resistance, Scratch resistance,cold and heat cycle, etc. Automatic computer control production ensures the stabilityof the product.The main raw material used in rena paint – resin is alsodeveloped by the Company itself.production, furtherguarantees the coating product Professionalism and applicability.

OUR FIVE BIG ADVANTAGES

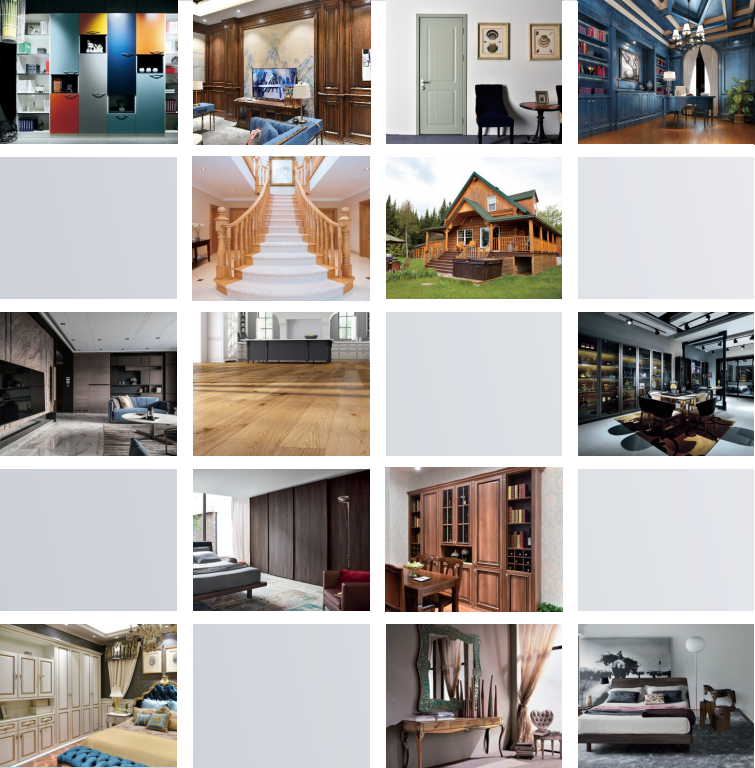

OVERALL SCOPE OF APPLICATION

Volontà Italia's research and development center has successfully developed high-quality waterbased wood lacquer, and Volontà Italia's waterbased paint system includes water base, primer and finish.

SAVE PRODUCTION COST

Compared with traditional solvent - based coatings, Volontà's water - based paint is more economical and practical. In the process of production, at least 20% reduction in the rate of blowout.

EASY TO OPERATE

Water - based paint is easy to understand and easy to operate. Not only for large industrial production, but also for individual small studios. It is a kind of paint with low input and high yield.

COST SAVING

Volontà Italy is an economical and practical coating. During the spraying process, you can reduce the overshoot rate by 20% compared to oil-based coatings. With the automatic circulation system, the reuse rate can reach 40%.

OUR FIVE BIG ADVANTAGES

OVERALL SCOPE OF APPLICATION

Volontà Italia's research and development center has successfully developed high-quality waterbased wood lacquer, and Volontà Italia's waterbased paint system includes water base, primer and finish.

SAVE PRODUCTION COST

Compared with traditional solvent - based coatings, Volontà's water - based paint is more economical and practical. In the process of production, at least 20% reduction in the rate of blowout.

EASY TO OPERATE

Water - based paint is easy to understand and easy to operate. Not only for large industrial production, but also for individual small studios. It is a kind of paint with low input and high yield.

COST SAVING

Volontà Italy is an economical and practical coating. During the spraying process, you can reduce the overshoot rate by 20% compared to oil-based coatings. With the automatic circulation system, the reuse rate can reach 40%.

ENVIRONMENTAL PROTECTION

Waterborne paint is the healthiest and most environmentally friendly product. VOC emissions are the lowest. It can effectively reduce the health and environment of production line. Can effectively protect the health of workers.

CUSTOMER CHOICE - OUR PURSUIT

What brand new brand furniture will the guests choose today? Safe furniture do not bring pollution dangerous furniture because of coating. Furniture without lead chromium and heavy metals.Odorless furniture and food containers.Furniture with very low VOC emissions effectively improve the working environment of factory workers and ensure the health of workers.

OUR COMMITMENT TO THE ENVIRONMENT

In 2001, the World Health Organization ruled that the maximum concentration of formaldehyde in homes was limited to 100 micrograms per cubic meter (0 . 1 – ppm). In Italy, the quota was included in the maximum indoor threshold of the Gazzetta Ufficiale n 2008. In 2004, the International Agency for Research on Cancer (IARC) declared carcinogenic formaldehyde. Since 2016, formaldehyde is no longer classified as a “suspected carcinogen” in EU countries, but as “probably carcinogenic”.

OUR COMMITMENT TO THE ENVIRONMENT: HEALTH AND NATURE

All paints are respectful of nature and construction workers benefit, they are exposed to healthy paints

OUR CORE IDEA IS TO SERVE CUSTOMERS

Whether in Italy or anywhere in the world, we guarantee prompt delivery and provide a complete pre and after sales service. In order to better meet the individual needs of our customers, we have assembled a professional team of 40 chemical experts and technicians, under whose professional guidance our customers can. Select the right coating in a timely and effective manner and maximize the performance of the product.